Shop Tools

Below are the shop tools, in alphabetical order, used in the treatments and enclosures described in this manual.

Adhesive Binding Vise

The “double-fan” adhesive binding we do in house involves the use of two special, made-for-the-purpose tools. The first of these is a vise and is used in the step following the chopping of the text block’s spine. At this point, the text block is a jogged stack of loose leaves. This vise holds the text block firmly while the adhesive and super are applied.

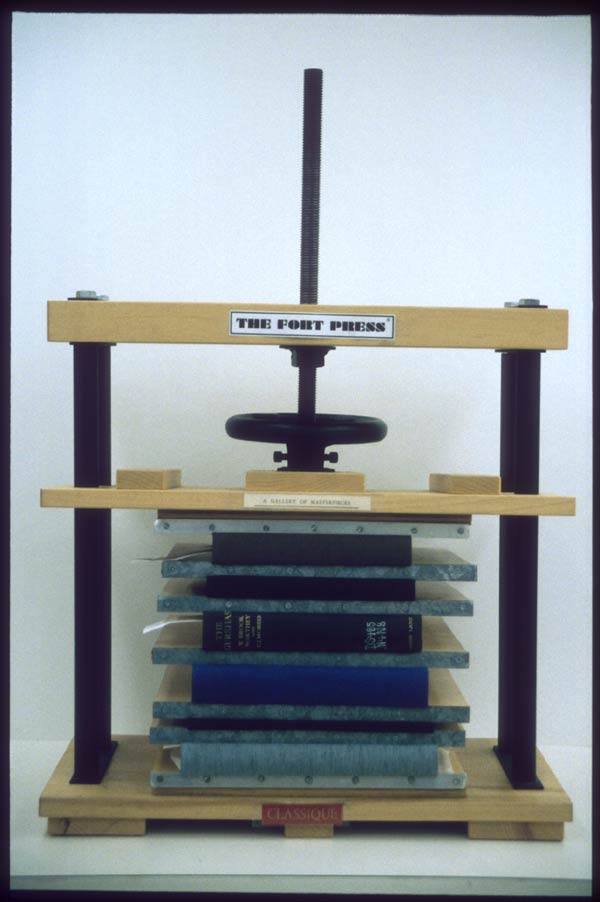

Adhesive Binding Press

This press is used to press a book that has just received an in-house adhesive binding. It holds the book firmly in place, but does not necessarily have to press the gutters to create deep hinges. Plastic-edged boards replace the metal-edged ones used to press books with a defined joint. These boards can be flipped over to provide more or less pressure on the hinge. This allows the book to maintain its original shape, especially if it is a paperback that has just been put into a hard cover.

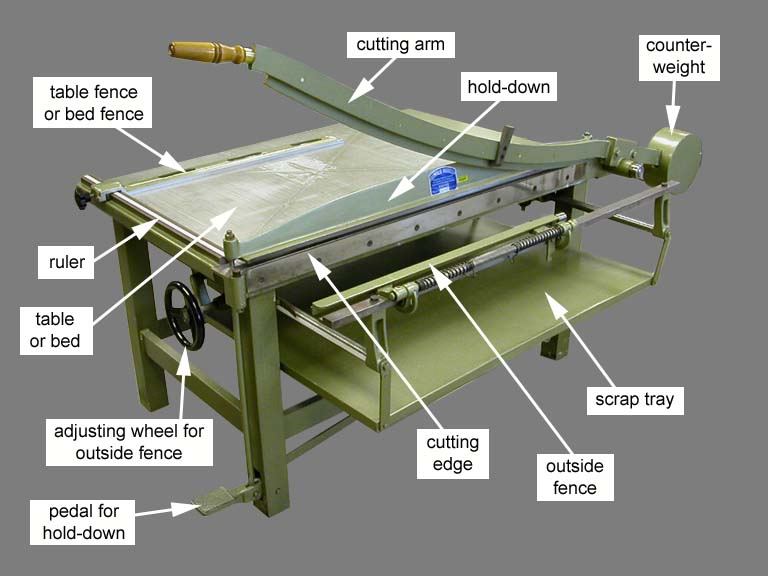

Board Shear

The board shear is the tool used to cut the various types of board used in conservation work. Its cutting action is that of scissors, as it cuts by means of two blades sliding against each other. The stationary cutting edge is the corner of its table (or bed). The moveable blade is the cutting arm. The blade of the cutting arm is sharpened to an angle only about 20 degrees acute of square, and the cutting edge of the table top is square, so the risk of cutting oneself by merely touching either blade is minimal. The board shear has a built-in ruler along the edge of the bed nearest the operator, a pedal-operated hold-down, and an outside fence which can occasionally prove handy for cutting certain materials to narrow widths. The board shear is also used to cut materials other than board, such as cloth, and paper.

Corner Rounder

This tool is used to round off corners, most commonly those of the grey-white board pamphlet-type binders made in-house, phase boxes, and the flaps of the inner structures of both wrappers and portfolio-type enclosures. As with the board shear, the hold-down is foot-pedal-operated, so again you need to be careful to keep fingers out of its way. There are also table-top corner rounders.

Crimper

This tool is used to impress creases into folder stock, gray/white board, or corrugated board, when making enclosures. The blade operates by means of a foot pedal, which simply lowers it onto the work.

Cutting Mats

These are the “self-healing” variety cutting mats. They are made of a material that fuses back together after being cut, so they can be cut on repeatedly for years before needing replaced.

Guillotine

This illustration shows our Challenge Titan 265 guillotine. It is an all-hydraulic guillotine, which means that both the cutting blade and the hold-down are powered hydraulically. The hold-down can be operated manually as well. Like the board shear, it has a movable fence for making any number of successive cuts, all to the same length and/or width. The guillotine differs functionally from the board shear and it is used to cut only paper. Its cutting action is that of a knife, and its single blade is razor-sharp. Once the work is positioned on the tool’s table and secured by the hold-down, the buttons (both) at the front are pushed and held to activate the blade. As a safety feature, if either button is released, the blade stops and retracts.

Job Backer

The Job Backer is used to hold books tightly, spine up, while backing them, i.e., shaping the spine into a curve. We also use it for oversize books when they are to tall to fit in a finishing press.

MEASUREpHASE

The MEASUREpHASE is used to measure an object, ordinarily a book, for the purpose of constructing an enclosure. It yields accurate measurements of three-dimensional objects, and helps when the book or object is a irregularly shaped, as books sometimes are.

Presses

Finishing Press

The finishing press is used to hold the text block of a book vertically, spine facing up, while the book is out of its case and repair treatments are in progress. Normally, the procedures performed while the text block is in the finishing press are the cleaning of the spine and the attachment of the new headbands, super, and spine liner. It acts as a vice, holding the book tightly, yet not damaging the text block.

Standing Press

Following completion of a spine or case repair, books are placed in a standing press for the adhesive to dry and to impress the joints (if any). Each book is placed between two edge boards, with a flat board at the top and bottom of the press’s workload. The last press pictured above is a large standing press used mostly for pressing large flat-paper items.

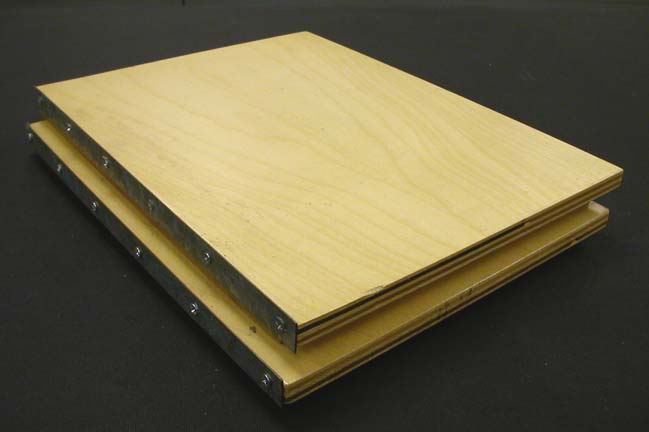

Edge Boards

Edge boards, aka metal-edge boards, are placed between books in a standing press. They are wooden boards with a strip of metal on one edge, which protrudes about ¼” beyond both flat surfaces of the board (resulting in a T-shaped cross-section). These edges fit into the hinge of the book and help to create a well-defined gutter between the back (spine) edges of the boards and the shoulders of the text block.

Flat Boards

Flat boards are used along with edge boards in the standing press. They are placed on the absolute bottom and top of the stack of work, to allow clearance, preventing the metal edges of the edge boards from being bent by the press as it is tightened down. They are also used at the bench with a weight to press a book or other object, spreading the weight out evenly.

Rivet Bucker

This tool is used to “buck” or join, the two halves of a rivet together. We use it mostly when making phase boxes.

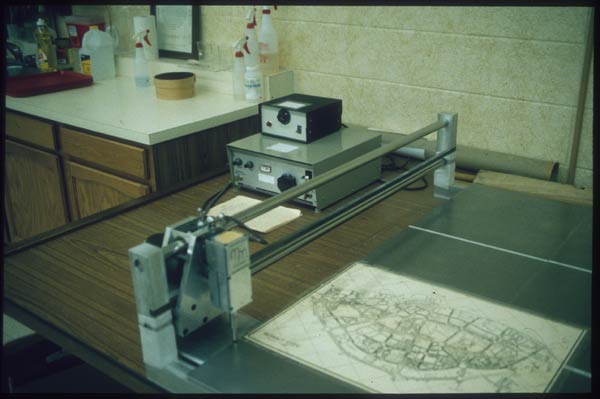

Ultrasonic Welder

This device, the Minter Welder, is used to join together two layers of polyester (Mylar) to encapsulate flat paper items such as maps and posters. Its tip generates ultrasound, which has an effect similar to that of heat, in that it fuses two pieces of Mylar along a very narrow and controlled line.