Small Cells Tackling Large Issues

Stacey Tam

Every time I finished cooking a meal, I was always surprised – and frankly, annoyed – at how much plastic would fill my trashcan afterward. Almost every ingredient that I cooked with contained some form of plastic packaging. Each broccoli crown was individually wrapped, and the beef had a plastic film over the styrofoam container. As someone who tries to be cognizant of my actions and their effect on the environment, I was bothered by my own excessive reliance on non-biodegradable plastic materials. Curious to see if I could successfully shop for groceries with items that did not contain plastic packaging, I headed to my local Costco store.

Aside from the items, one positive feature of Costco is that they do not provide plastic bags to consumers in order to reduce waste and operating costs. Instead, shoppers stack items in the cart and use cardboard boxes when necessary. When I shopped at other grocery stores, it was easy to build up a pile of plastic bags. Walking around the store, I was hard-pressed to find a product that did not use plastic packaging; most of the items that fit my specifications were fruit. There was a pile of pineapples in a large wooden crate as well as smaller boxes of apples and oranges that used cardboard instead. The alcohol section was also semi-plastic-free, but some of the bottles were wrapped in plastic around the top. Many items were in cardboard boxes, but a thin layer of plastic was added on the outside to make them sturdier and water-resistant. Interestingly enough, I did see a Hellman’s mayonnaise jar proudly proclaim that it was made out of 100% recycled plastic. Finally, some pickled food was offered in glass jars and metal cans. In a store that seemed to stock any item a customer could ever want, there were only three options that lacked any plastic – fruit, alcohol, and pickled goods.

As if the store was mocking me one last time, I happened to look up at the shelves overhead on my way out, only to see more plastic film used to wrap crates of items together. Most, if not all of the products, were probably wrapped together on crates for ease of transportation.

My personal exploration only examined one sector that used plastic, and its use was both deeply ingrained and excessive. When considering the multitudes of industries and people around the world, it’s no surprise that we are approaching a plastic crisis. Unlike other biodegradable materials like paper, plastic requires hundreds, if not thousands of years to degrade. All of the plastic that we produce accumulates, and we currently lack any method to completely break down or recycle the durable material. Instead, we struggle to find enough space to store the plastic out of sight, eventually spilling into the environment. It is now a common sight to see coasts polluted with plastic and trash, such as this beach in Lebanon shown below.

In many environmental campaigns about plastic use, organizations push for more eco-friendly consumer habits, such as recycling containers, shying away from one-time-use plastic grocery bags, and carrying reusable silverware. The behavioral changes will help slow future consumption and production of plastic, but what about the tons of plastic that have already packed our landfills and polluted our oceans? Are we doomed to wait many years for the material to degrade? Ideonella sakaiensis, a bacterium found at a recycling plant in Sakai, Japan, may present a potential solution for both plastics that have been sitting in landfills for years as well as newly-produced plastics. This bacterium The behavioral changes will help slow future consumption and production of plastic, but what about the tons of plastic that have already packed our landfills and polluted our oceans?uses plastic as a carbon source, degrading it back to two molecules that can be remolded into plastic or used to produce other chemicals, like antifreeze. Currently, scientists are focusing on how to utilize the novel bacteria to recycle more efficiently. While the discovery of this bacteria may seem like a beacon of hope for our environmental issues, biological, economic, and implementation problems prevent I. sakaiensis from being a viable solution in the near future.

The Scope of Our Problem

Before examining the specifics about I. sakaiensis, more context is needed on the scope of our plastic consumption to determine whether this bacteria can properly tackle it. Unsurprisingly, our plastic production has been growing exponentially since the 1950s, when it started to become a popular material (Geyer, 2017). A Science article by Roland Geyer calculated that roughly 8.3 billion tons of plastic have been produced since then; only 500 million tons have been recycled (Geyer, 2017). Overall, 4.9 billion tons still sit in landfills or are scattered around the Earth, ruining ecosystems (Geyer, 2017). Unsurprisingly, the packing sector is the biggest consumer of plastic, especially the food industry. Most, if not all, food items are packaged individually for sanitary reasons, which partially accounts for my difficulty in finding plastic-free items at Costco. One consumer can quickly accumulate many pounds of plastic over the years just by visiting the grocery store. Our need to wrap every good in plastic extends outside of the food industry. I recently ordered a new case for my phone, and the box came neatly wrapped in plastic. I wasn’t worried about the case being “dirty,” but the plastic still served a crucial purpose – the intact wrap indicated that no one had tampered with the product. As a consumer in the era of online shopping, it’s reassuring to have these small signs that our product was delivered unharmed and safely. As someone concerned for the environment, I’m conflicted about my need to have items wrapped. Either way, with companies wrapping everything in plastic and billions of people purchasing products, our plastic consumption quickly becomes overwhelming.

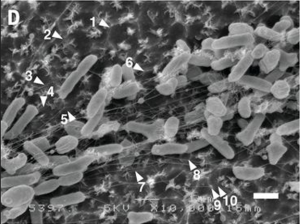

Zooming in on Bacteria

With mountains of plastic growing around the world, scientists looked to nature for a potential solution. After all, nature has proven to be hardy time after time by adapting to ever-changing living situations. Aware of the disposition for bacteria to evolve and useHere, they isolated I. sakaiensis, a strain that utilized enzymes, or proteins that catalyze specific chemical reactions, to break down and use plastic as a carbon source. whatever material they can find, scientists sifted through waste outside of a bottle-recycling plant to isolate a strain capable of degrading plastic (Yoshida, 2016). Here, they isolated I. sakaiensis, a strain that utilized enzymes, or proteins that catalyze specific chemical reactions, to break down and use plastic as a carbon source.

Taking a closer look at the bacteria, scientists found that it could only degrade polyethylene terephthalate, or PET, only one of the many types of plastic (Yoshida, 2016). PET is used to make plastic water bottles and polyester clothes (Snowden, 2020). While researchers focused on the bacteria’s ability to degrade plastic involved with food, such as disposable water bottles, the fast fashion industry is also one of the main contributors to plastic waste. The growing trend to purchase copious amounts of low-quality clothes only to dispose of them a few months later has filled our ocean and landfills with additional plastic. The first published paper that characterized this strain in March 2016 noted that I. sakaiensis could break down a film of plastic in 6 weeks at 30 °C, or 86 ° F (Yoshida, 2016). Researchers were excited to see that the bacteria’s operating temperature was similar to a warm summer day, as the low temperature indicated that no added heat was needed to run the reaction. However, the rate was slow. If it continued at its current pace, it would take forever to degrade one ton of plastic, let alone the billions of tons of plastic around the world. However, other companies have made advances to improve the rates of the enzyme to make it more useful. Scientists hope to be able to optimize the natural recycler to use for commercial purposes. There seemed to be endless possibilities if they could get the bacteria to work, imagining smaller recycling bins in our own homes to immediately dispose of plastic.

Optimizing Nature’s Machinery

Since the original discovery in 2016, scientists have already modified the bacteria to produce more efficient enzymes. Carbios, a French company, has produced a version of I. sakaiensis that broke down 90% of one ton of plastic bottle wastes within 10 hours (Snowden, 2020). The experiment was done at 72 °C, or 162 °F (Snowden, 2020). Although not as low as the original temperature, the increased efficiency of the enzyme came at the cost of requiring more heat energy. In fact, 72 °C is still relatively low as compared to other popular commercial reactions. Carbios’ reinvented bacteria was not only faster than the original strain but also enhanced which products it could break down. According to Professor Alain Marty, the lead researcher of the Carbios team, their version can also “depolymerize any PET – transparent, colored, opaque, amorphous as well as crystalline, fibers – into any kind of PET product” (Snowden, 2020). The only downside was that the degradation process requires an extra step – the bottles need to be “ground up and heated” before the enzymes can be added in (Carpenter, 2021). The company hopes to open a factory in 2024 that specializes in recycling plastic, but there are many added challenges the team and other researchers need to overcome before creating a fully functional solution to our plastic crisis.

Polluted Plastic Food

While scientists have begun to understand and implement ways to utilize I. sakaiensis, the bacteria still struggle with some aspects of the degradation process. Firstly, other chemicals are used in combination with PET when manufacturing plastic products to induce certain characteristics, such as making the bottle sturdier or more flexible (Carpenter, 2021). While Carbios’s strain of bacteria can break down plastic, they fail to consider how the bacteria will handle these additives. Additionally, if the bacteria are released in landfills to degrade old plastic, biologists fear that the released chemicals would further damage the environment (Carpenter, 2021). Secondly, I. sakaiensis can also only break down one type of plastic – PET, which accounts for a mere 1/5 of the world’s plastic production (Cornwall, 2021). Plastic is typically a fusion of many different types of plastics, so it’s hard for I. sakaiensis to isolate the PET and digest the mix (Cornwall, 2021). Other bacteria that can break down other plastics will have to be similarly discovered and optimized for commercial use, which is highly time-consuming. Finding other enzymes or bacteria to break down the other plastics may also prove to be difficult, as the other plastics have stronger bonds, such as polypropylene that is used in strong bottles like milk cartons (Cornwall, 2021). While scientists have made progress to figure out how to utilize I. sakaiensis, many questions need to be answered before they can move forward with this as a viable solution.

Back to the Money

In addition to issues with optimizing the bacteria, economic factors also influence how practicable this solution is. The biggest issue facing large-scale use of I. sakaiensis is the expense. Added chemicals and heat are required to run the degradation reaction to recycling the plastic, driving up the cost of recycling plastic using the bacteria (Snowden, 2020). Since the added cost makes recycled plastic more expensive than virgin plastic, it can be difficult to convince companies to pay the added cost to protect the environment. However, the biologically-recycled plastic is not only competing with newly-produced plastic – it is also competing with lower-quality, recycled plastic that is also sold cheaply and used in products such as carpet (Snowden, 2020). Thus, if a company would like to use recycled plastic in their products, they would rather purchase the lower-quality version rather than the bacterially-recycled one. It is difficult for Carbios and other companies to pursue I. sakaiensis as a viable solution if they cannot identify a customer for their product.

Dumping Bacteria in Landfills

Aside from the biological and economic issues with utilizing I. sakaiensis, researchers also need to formulate a safe method to degrade plastics in landfills. As mentioned before, haphazardly releasing the bacteria into landfills to selectively degrade PET is not an option; they need to consider the chemicals released, the potential of a mutation within the bacteria that cause issues in the future, and the probability of the bacteria finding all of the plastic at that site. If releasing the bacteria into landfills is not an option, how do we sort through millions of tons of trash to pick out plastic that can be degraded? We have to not only pick out plastic in landfills but also plastic in the ocean and environment as well, which requires a substantial amount of manpower. Carbios envisions creating factories or even small boxes within our homes to recycle plastic, but these solutions have a limited reach (Snowden, 2020). Although experts in other fields can help scientists solve this implementation issue, we currently lack a workable solution to collect pre-existing plastic.

Are We Doomed…?

Although scientists are racing to develop a solution, they are doubtful whether they will be able to utilize the technology quickly enough to solve the plastics pollution issue. Faced with many questions and issues to address, they understand that other actions need to be taken now to prevent further pollution of our world (Carpenter, 2021). So, what do we do? We focus on changing consumer habits. As consumers, we can leverage our buying power to demand companies to use less plastic, whether that be within the actual products or during shipping. Additionally, we can actively find ways to use fewer plastics in our own lives. Instead of using many plastic bags at the grocery store, we can transition to using tote bags and other cloth bags to hold our items; not partaking in the fast fashion trend will also help substantially reduce plastic use. Finally, we can also learn to consume less on principle. By learning to live with less plastic, we can help buy enough time for scientists to try and reverse our plastic crisis.

REFERENCES

Carpenter, S. (2021, March 17). The Race to Develop Plastic-Eating Bacteria. Forbes. Retrieved November 22, 2021, from https://www.forbes.com/sites/scottcarpenter/2021/03/10/the-race-to-develop-plastic-eating-bacteria/.

Cornwall, W. (2021, July 1). Could plastic-eating microbes take a bite out of the recycling problem? Science. Retrieved November 22, 2021, from https://www.science.org/content/article/could-plastic-eating-microbes-take-bite-out-recycling-problem.

Geyer, R., Jambeck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7). https://doi.org/10.1126/sciadv.1700782

Snowden, S. (2020, April 12). New enzyme breaks down plastic in hours and enables high-quality recycling. Forbes. Retrieved November 22, 2021, from https://www.forbes.com/sites/scottsnowden/2020/04/11/new-enzyme-breaks-down-plastic-in-hours/.

Yoshida, S., Hiraga, K., Takehana, T., Taniguchi, I., Yamaji, H., Maeda, Y., Toyohara, K., Miyamoto, K., Kimura, Y., & Oda, K. (2016). A bacterium that degrades and assimilates poly(ethylene terephthalate). Science, 351(6278), 1196–1199. https://doi.org/10.1126/science.aad6359